In today's world of rapid technological development, the aerospace manufacturing industry, as a representative of high-precision and cutting-edge fields, has increasingly higher requirements for processing accuracy, efficiency and material utilization. The laser cutting machine, with its unique advantages of high precision, high efficiency and non-contact processing, has become an indispensable precision tool in the aerospace manufacturing industry. This article will explore in depth the application, advantages and profound impact of laser cutting machines in the aerospace manufacturing industry on the development of the industry.

1. Application of laser cutting machines in the aerospace manufacturing industry

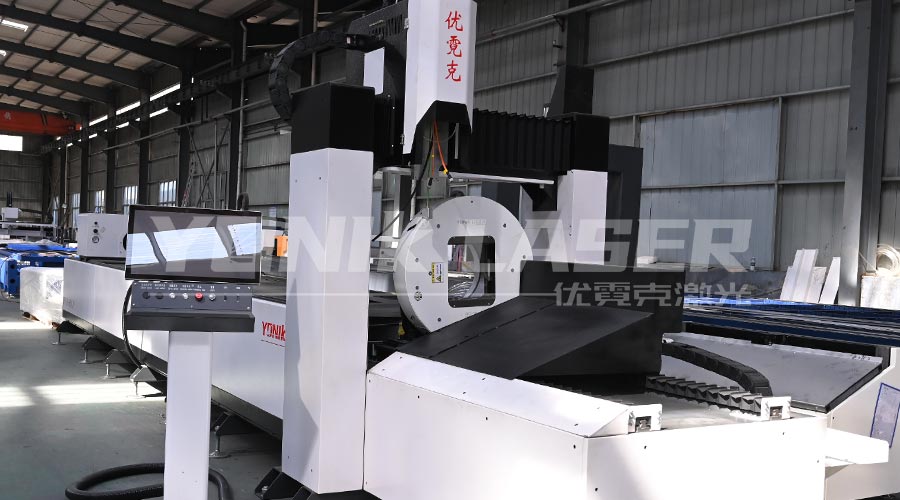

The aerospace manufacturing industry has extremely high requirements for the accuracy, strength and lightness of parts. Laser cutting machines play a vital role in this field with their fine cutting capabilities and adaptability to a variety of materials. From aircraft skins, wing frames to rocket engine casings and satellite structural parts, laser cutting machines can achieve precise and efficient cutting processing.

In the aircraft manufacturing process, laser cutting machines are widely used to cut lightweight and high-strength materials such as aluminum alloys and titanium alloys. These materials require not only high cutting accuracy, but also good edge quality and surface finish. Through its high-energy-density laser beam, the laser cutting machine can quickly melt and vaporize the material to achieve fine cutting, while reducing the heat-affected zone and ensuring the flatness and finish of the cut surface.

In addition, laser cutting machines also play an important role in the manufacture of rockets and satellites. Rocket engine casings, fuel tanks and other components need to withstand extremely high temperatures and pressures, and have extremely high requirements for the cutting accuracy and edge quality of the materials. Laser cutting machines can easily cope with these challenges and provide high-quality cutting solutions for the aerospace manufacturing industry.

2. Advantages of laser cutting machines in the aerospace manufacturing industry

High precision: The laser cutting machine uses a computer to precisely control the moving trajectory of the laser beam, which can achieve micron-level cutting accuracy. This high-precision cutting not only meets the strict requirements of the aerospace manufacturing industry for the accuracy of parts, but also improves the overall performance and reliability of the product.

High efficiency: The cutting speed of the laser cutting machine is much higher than that of the traditional mechanical cutting method. In the aerospace manufacturing industry, time is money and efficiency is life. The efficient cutting capability of the laser cutting machine greatly shortens the production cycle, reduces production costs, and improves the market competitiveness of enterprises.

Strong adaptability: Laser cutting machines are suitable for cutting a variety of materials, including metals, non-metals, and composite materials. In the aerospace manufacturing industry, there are many types of materials with different properties. With its strong adaptability, laser cutting machines can easily cope with the cutting needs of various materials.

High degree of automation: Laser cutting machines can be closely integrated with computer control systems to achieve automated cutting. This not only improves production efficiency, but also reduces the risks and costs of manual operations. In the aerospace manufacturing industry, automated production has become a trend, and the automated cutting capabilities of laser cutting machines just follow this trend.

3. The profound impact of laser cutting machines on the aerospace manufacturing industry

The application of laser cutting machines has had a profound impact on the aerospace manufacturing industry. It not only improves production efficiency and quality, but also promotes technological innovation and industrial upgrading in the industry. With the continuous advancement of laser cutting technology and the continuous expansion of its application, the aerospace manufacturing industry will usher in a broader development prospect.

Promote technological innovation: The emergence and development of laser cutting machines has provided new processing methods and technical paths for the aerospace manufacturing industry. It has inspired companies to explore and apply new technologies and promoted technological innovation and development in the industry.

Promote industrial upgrading: The widespread application of laser cutting machines has promoted the industrial upgrading of the aerospace manufacturing industry. It improves production efficiency and quality levels, reduces production costs and risks, and provides enterprises with a more efficient, environmentally friendly and intelligent production method. At the same time, the application of laser cutting machines has also promoted the development and improvement of related industrial chains.

Assist in sustainable development: In the aerospace manufacturing industry, the utilization rate and recovery rate of materials are of great significance for achieving sustainable development. With its high precision, high efficiency and non-contact processing characteristics, laser cutting machines can maximize the utilization rate and recovery rate of materials, reduce material waste and environmental pollution. This helps the aerospace manufacturing industry achieve green production and sustainable development.

IV. Conclusion

As a precision tool in the aerospace manufacturing industry, the laser cutting machine has injected new vitality and power into the development of the industry with its advantages of high precision, high efficiency, strong adaptability and high degree of automation. It not only improves production efficiency and quality levels, but also promotes technological innovation and industrial upgrading in the industry. In the future, with the continuous advancement of laser cutting technology and the continuous expansion of its application, laser cutting machines will play a more important role in the aerospace manufacturing industry and contribute to the vigorous development of the industry.

2025-07-22

2025-07-21

2025-07-19