In the wave of modern manufacturing, laser cutting technology has become a shining star in the field of metal processing due to its high efficiency, precision, and non-contact processing characteristics. In particular, the laser machine to cut metal has won the favor of many enterprises with its excellent performance and wide range of applications. This article will take "laser machine to cut metal" as the core keyword, and deeply discuss its advantages, applications and factors to be considered when selecting in the field of metal processing.

1、 Overview of laser machine to cut metal

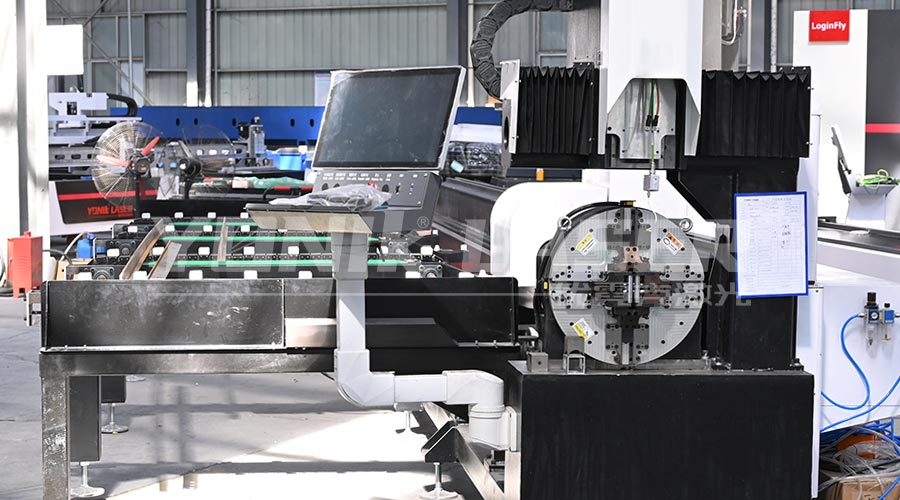

Laser machine to cut metal is an advanced equipment that uses high-energy density laser beam to cut metal plates quickly and accurately. It adopts a computer control system to convert the designed graphics or text into a laser cutting path. Through the high energy density of the laser beam, the metal sheet is quickly melted and vaporized in a very short time, thus achieving the cutting purpose. The laser machine to cut metal has the advantages of fast cutting speed, high precision, good edge quality and high material utilization rate, and is widely used in aerospace, automobile manufacturing, electronics, machinery manufacturing and other fields.

2、 Advantages of laser machine to cut metal

High precision: laser machine to cut metal adopts non-contact cutting mode, which avoids tool wear and cutting error caused by traditional mechanical cutting, and ensures cutting precision. At the same time, the high energy density of the laser beam makes the cutting edge smooth and burr free, greatly improving the cutting quality.

High efficiency: The laser machine to cut metal has extremely fast cutting speed and can complete the cutting task of a large number of metal plates in a short time. This not only improves production efficiency, but also reduces production costs.

Flexibility: The laser machine to cut metal can cut metal plates of various shapes and sizes to meet the needs of different industries and fields. At the same time, it can also be flexibly adjusted according to design requirements to achieve personalized customization.

Energy saving and environmental protection: The laser machine to cut metal uses laser beam to cut, without using the cutting fluid and cutting tools required by traditional cutting methods, reducing energy consumption and waste emissions, in line with the development trend of green manufacturing.

3、 Application of laser machine to cut metal

Laser machine to cut metal is widely used in the field of metal processing. In the aerospace field, it is capable of high-precision cutting of difficult to machine materials such as aluminum alloys and titanium alloys, ensuring the structural strength and safety of aircraft, rockets, and other aerospace vehicles. In the field of automobile manufacturing, the laser machine to cut metal can quickly and accurately cut car body, frame and other parts, improving production efficiency and quality. In addition, in the field of electronics and electrical appliances, the laser machine to cut metal can also achieve micron level precision cutting to meet the precise installation and connection requirements of electronic components.

4、 How to select the appropriate laser machine to cut metal

When selecting laser machine to cut metal, enterprises need to consider the following factors:

Processing demand: select the appropriate model and power of laser machine to cut metal according to the processing demand of the enterprise. Different metal sheets and cutting thicknesses require different laser powers and cutting speeds.

Equipment quality: select the supplier of laser machine to cut metal with good reputation and quality service to ensure the quality and after-sales service of the equipment.

Convenience of operation: Consider the ease of operation and level of intelligence of the device. Modern laser machine to cut metal is usually equipped with advanced control system and human-computer interface, which makes the operation more simple and intuitive.

Cost performance ratio: on the basis of comprehensive consideration of equipment quality, performance, price, after-sales service and other factors, choose the laser machine to cut metal with the highest cost performance ratio.

5、 Summary and Prospect

As an efficient and accurate tool in the field of metal processing, the laser machine to cut metal has become the first choice of many enterprises with its excellent performance and wide range of applications. With the continuous development and upgrading of the manufacturing industry, the laser machine to cut metal will play an important role in more fields. At the same time, with the continuous progress and innovation of technology, the laser machine to cut metal will also be more intelligent, automated and green.

In short, the laser machine to cut metal is playing an increasingly important role in the field of metal processing with its efficient, accurate and non-contact processing characteristics. It is of great significance to select a suitable laser machine to cut metal for improving the production efficiency and quality of enterprises.

2025-07-22

2025-07-21

2025-07-19